In the realm of tools, the humble screwdriver holds a position of unquestionable importance. From household fixes to intricate mechanical work, its versatility is unparalleled. Yet, despite its seemingly straightforward purpose, the manner in which we employ this indispensable tool is often fraught with inefficiency and even danger. In this article, we delve into the common misuses of screwdrivers and explore how we can maximize their utility while ensuring safety.

1. Treating It as a Hammer

Perhaps one of the most common misuses of the screwdriver is employing it as a makeshift hammer. Whether out of convenience or ignorance, many individuals resort to tapping the handle of the screwdriver to drive in nails, adjust small objects, or even break through stubborn materials. This practice not only compromises the integrity of the screwdriver but also increases the risk of injury.

Solution: Instead of subjecting the screwdriver to undue stress, invest in a proper hammer for pounding tasks. By using the right tool for the job, you not only preserve the longevity of your screwdriver but also ensure your safety and efficiency.

2. Incorrect Size Selection

Another prevalent mistake is using a screwdriver that does not match the size of the screw head. Attempting to turn a screw with an ill-fitting screwdriver often leads to slippage, damaging both the screw head and the surrounding surface. Moreover, excessive force exerted in such situations can result in hand injuries or the stripping of the screw head.

Solution: Take the time to select the appropriate screwdriver size for the task at hand. Match the width and shape of the screw head to the corresponding screwdriver tip to achieve a snug fit. Not only does this ensure proper engagement, but it also minimizes the risk of slippage and damage.

3. Neglecting Grip and Torque

Effective use of a screwdriver relies heavily on maintaining a firm grip and applying the right amount of torque. However, many individuals overlook the importance of these factors, leading to inefficient operation and potential injuries. Weak or improper grip can cause the screwdriver to slip, resulting in damage to the screw head or surrounding surfaces, while excessive torque can strain muscles and joints.

Solution: Ensure a secure grip on the screwdriver handle, positioning your hand comfortably to maximize control. Apply steady pressure while turning the screw, adjusting the torque as needed based on the resistance encountered. If additional force is required, consider using a screwdriver with a larger handle or employing leverage-enhancing techniques such as bracing the screwdriver against a solid surface.

4. Using the Wrong Type of Screwdriver

Screwdrivers come in various types and designs, each suited to specific tasks and screw heads. Using the wrong type of screwdriver not only makes the job more difficult but also increases the likelihood of damage to both the screw and the screwdriver itself. For instance, attempting to drive a Phillips head screw with a flathead screwdriver can lead to slippage and stripping of the screw head.

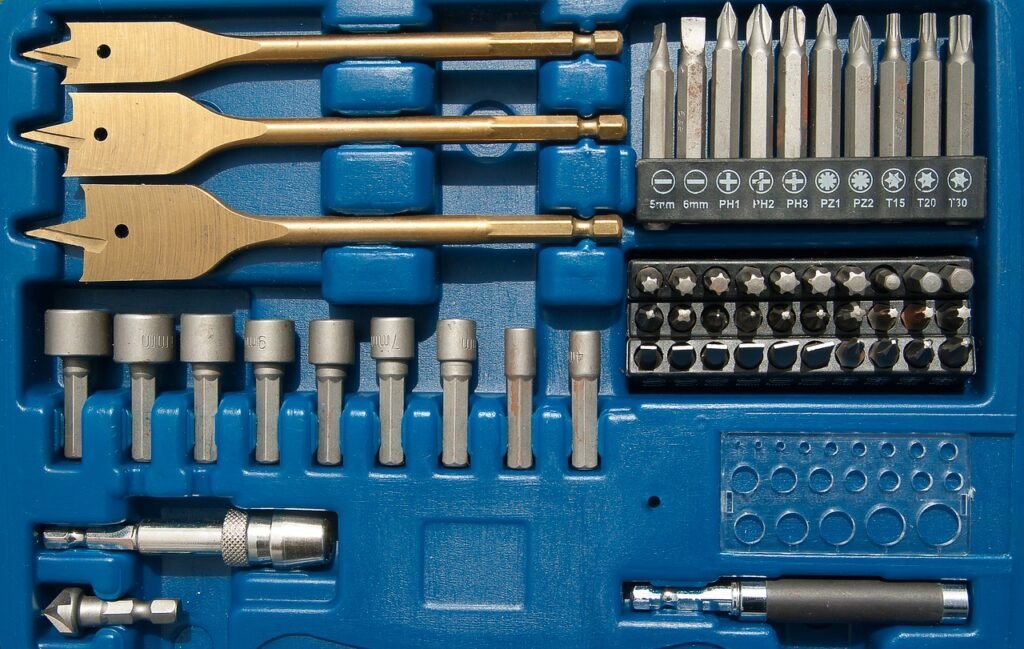

Solution: Familiarize yourself with the different types of screwdrivers and their corresponding applications. Invest in a comprehensive set of screwdrivers that includes various tip types, such as flathead, Phillips, Torx, and hex, to ensure you have the right tool for any job. Take the time to identify the type of screw head before selecting the appropriate screwdriver.

5. Overlooking Maintenance

Like any tool, screwdrivers require regular maintenance to ensure optimal performance and longevity. However, many individuals neglect this aspect, leading to the deterioration of the tool’s effectiveness over time. Rust, debris buildup, and wear and tear can all compromise the functionality of the screwdriver, resulting in poor performance and potential safety hazards.

Solution: Incorporate routine maintenance into your tool care regimen to keep your screwdrivers in top condition. Clean the tool after each use, removing any dirt, grease, or debris that may have accumulated. Store screwdrivers in a dry, climate-controlled environment to prevent rust and corrosion. Periodically inspect the tool for signs of wear, such as bent or chipped tips, and replace as needed to maintain optimal functionality.

In conclusion, the widespread misuse of screwdrivers highlights the need for a greater understanding of proper tool usage and maintenance. By avoiding common pitfalls such as using screwdrivers as hammers, selecting the wrong size or type, neglecting grip and torque, and overlooking maintenance, we can maximize the utility and lifespan of these essential tools while ensuring safety and efficiency in our endeavors. Let’s unlock the full potential of the screwdriver and elevate our craftsmanship to new heights.